To survive, almost all animal life types require oxygen. It is taken in through breathing or resorption if it is dissolved in water. However, oxygen is hazardous to the majority of living things in high amounts.

O2 is a necessary component of every combustion and corrosion process.

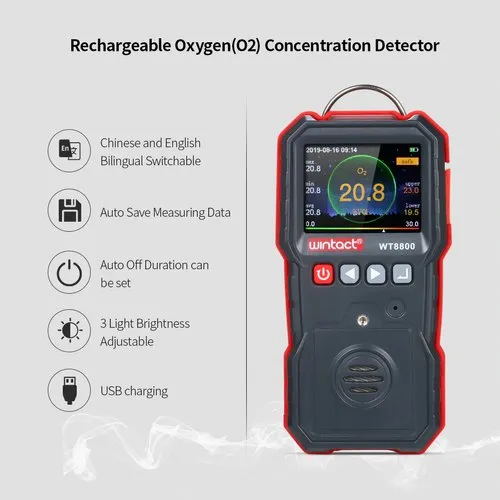

In addition to being used in medicine, oxygen is crucial for the metalworking industry since it can combine with practically every element to generate compounds. Additionally, oxygen plays a role in a variety of corrosion and combustion processes.A room’s oxygen levels (https://adkinstruments.in/products/room-oxygen-level-meter) are constantly monitored by an oxygen depletion alarm or oxygen deficiency monitor, which alerts occupants when levels are too low.

Wall-mounted oxygen depletion alarms are placed close to gas storage tanks for nitrogen, helium and argon.

If a gas that is being stored leaks or The oxygen sensor detects low oxygen levels and displays them on the monitor if one of the stored gases is accidentally discharged or seeps into the atmosphere.

An alarm will automatically sound to alert the room’s inhabitants of an oxygen shortage if the oxygen level falls too low.

An oxygen deficiency monitor may also serve as a room air controller in specific circumstances, turning on fans to introduce fresh air.

In every room or enclosed space where low oxygen levels are possible, oxygen deficiency alarms or monitors are essential.

Normal Air Oxygen Levels

Dry air has a nitrogen content of 78.09% and an oxygen content of 20.95% 0.04% carbon dioxide, 0.03% argon, and trace amounts of other gases.

normal pressures and temperatures, Humans are thought to function best when there is 20.9% oxygen in the air at typical pressures and temperatures. Hypoxia (lower oxygen levels) starts to happen when oxygen levels fall below 19.5%. Although the air is deemed oxygen-deficient, it is nonetheless regarded to be quite safe for persons who have acclimated their bodies to reduced oxygen levels or for short periods of time.

What Justifies the Use of Oxygen Deficiency Monitors?

Under 16% oxygen saturation is harmful for human life. The problem is that the oxygen shortfall might not be immediately apparent because the difference between 16% and 21% is often made up of inert, odourless gases like nitrogen, argon, or carbon dioxide. Low oxygen levels might result in sudden unconsciousness or death without warning.

What Situations Call for Oxygen Deficiency Monitors? What Situations Call for Oxygen Deficiency Monitors?

Any location where low oxygen levels are possible uses oxygen depletion alarms. While most people picture a closed space like an aeroplane or submarine, a room where pressurised cylinders of hydrogen, helium, argon, or nitrogen are kept is a much more typical example. The depressurization of the gas storage system caused by a leaking hose or fitting can drastically reduce the amount of oxygen in the space.

The following are some examples of stored gases for which oxygen depletion warnings are required:

In hospitals, nitrous oxide or nitrogen is used.

MRI equipment cooled with liquid helium

For cryo-biology, IVF, cryosurgery, or other sorts of cryogenic research, liquid nitrogen, helium, or argon . Oxygen monitors should be installed anywhere there is a risk of gas leaks. Place one oxygen monitor in any room where you store inert gases and in any room where these gases are used. This way, if you have a helium, argon, or nitrogen spill — for instance, in a university science lab — the oxygen sensor will detect the lower levels of oxygen and sound the alarm.

Oxygen monitors can be mounted on the wall using a bracket and screw, then connected via plug-in-the-wall power supply. Alternately, oxygen monitors can be hardwired with the services of an electrician. It’s your choice. We recommend that oxygen monitors be installed 3 to 5 feet off the ground, and 3 to 5 feet away from any obstacle, such as a gas tank.

Oxygen monitors deliver peace of mind that your employees and your facility are protected from the hazardous side effects of a gas leak. They may be required by industry regulations. To get an industry-leading oxygen monitor that’s maintenance-free, look to PureAireOxygen deficiency at levels below 16% is dangerous for human life. The challenge is that the difference between 16% and 21% is typically made up of inert, odorless gases like nitrogen, argon or carbon dioxide, so the oxygen deficiency may not be noticed immediately. If oxygen levels remain low, sudden unconsciousness or death without symptoms may occur.

Where are Oxygen Deficiency Monitors Used?

Oxygen depletion alarms are used in any place where low oxygen levels can occur. While most people think of a closed environment like an airplane or submarine, a much more common example is a room where pressurized cylinders of hydrogen, helium, argon, or nitrogen are stored. If a hose or fitting leaks, the depressurization of the gas storage system can rapidly lower the oxygen level in the room.

Examples of stored gases where oxygen depletion alarms are necessary include:

Nitrous oxide or nitrogen used in hospitals

Liquid helium to cool MRI machines

Liquid nitrogen, helium or argon for cryo-biology, IVF, cryosurgery or other types of cryogenic research

Liquid nitrogen to package meats, fruits, or dairy

Argon or other shield gases for welding

Nitrogen and argon used in 3D printing

Argon or other inert gases for fire suppression

While carbon dioxide could be added to this list, common practice is to use a CO2 Safety Alarm to measure high CO2 levels instead of an oxygen deficiency alarm.

OSHA Requirements for Oxygen Depletion Alarms

OSHA’s 29 CFR 1910.146, “Permit Required Confined Spaces,” contains the requirements for practices and procedures to protect employees in general industry from the hazards of entry into permit-required confined spaces.

The standard defines an oxygen-deficient atmosphere as any atmosphere containing less than 19.5 percent oxygen by volume. Any atmosphere that contains less than 19.5 percent oxygen is hazardous and may not be entered by unprotected workers.

The device alarm and warning levels should be where the oxygen concentration is below 19.5% or above 23.5% oxygen concentration levels.

NIH Oxygen Monitoring Devices Protocols

While not law or an OSHA regulation, the National Institutes of Health Protocol for use and maintenance of Oxygen Monitoring Devices has been established to provide guidance on the installation, maintenance, and calibration of oxygen monitoring devices in animal and laboratory areas in all NIH owned and leased buildings. It states:

“An oxygen monitoring device shall be installed in any indoor location where compressed gases or cryogenic liquids are stored and/or dispensed in manner that could create the potential for the displacement of oxygen. At a minimum, the following factors should be used in determining if a device should be installed: manufacturer (e.g., magnet) guidance, volume of gas used, location of gas, and air changes/hour in the room/area. The 2008 NIH DRM notes that both ‘carbon dioxide manifold rooms… [and] nitrogen holding rooms and shall include oxygen level monitoring alarms’ (section 8, pages 8-80). Additionally, compressed gases or cryogenic liquids shall not be located or dispensed in any indoor location that does not have proper ventilation.